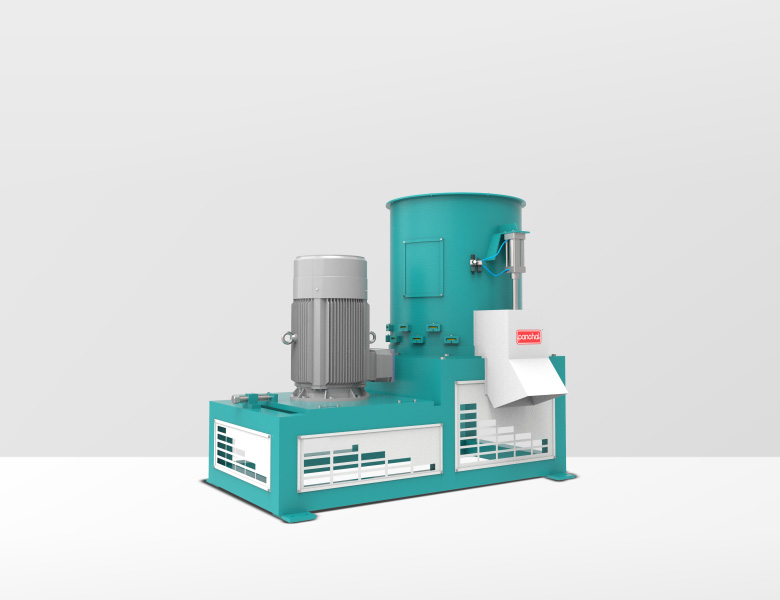

Agglomerator Densifier Machine

The D-Series agglomerator is a revolutionary plastic recycling machine that shreds and pressurizes plastic waste, heating it to optimal processing temperatures. This thermal transformation yields highly viscous material, which is then densified into easily manageable cubes upon the introduction of cold water.

Agglomerator Densifier Machine

The D-Series Agglomerator is a batch-operated machine that is used to process plastic waste. The machine has a processing chamber that is loaded with the waste material before the process begins. The high-energy blades shred the material and press it under the rotor, which heats the material to the processing temperature.

At this temperature, the material becomes highly viscous. Subsequently, cold water is injected into the process, which causes the material to densify. The resulting dense cubes are easy to feed into an extruder for further processing.

The D-Series agglomerator offers a myriad of benefits, including high efficiency, versatile processing, quality output, and sustainable impact. It optimizes the recycling process, reducing waste volume and streamlining operations.

Elevate your recycling efforts with the D-Series agglomerator. Contact us today to explore how this cutting-edge machine can empower your recycling facility and revolutionize your plastic recycling processes.

Key Features of Our Agglomerator Densifier

- Rapid Recycling Machine: Processes plastic waste in just 5 to 7 minutes

- Energy-efficient operation: No additional heating required

- User-friendly design: Requires minimal labor and training

- High-quality granule production: Yields uniform, manageable plastic granules

- Color customization flexibility: Tailor recycled plastic color to meet precise requirements

- Various sizes available: Match your plastic recycling volume and speed needs

- Versatile plastic compatibility: Capable of handling various plastic types

- Robust construction ensures long service life

Applications

The densifier is a machine used to recycle plastic waste. It operates by taking the plastic waste and then using heat to melt it into a gooey substance that can be molded. Then, it squashes this soft plastic into small, dense cubes when cold water is added.

- Plastic films such as LDPE

- HDPE packaging and containers

- PP film and raffia

- Woven sacks materials

- FIBC/jumbo bags

- Industrial plastic scrap

- Plastic fiber materials

- Multilayer packaging films

These cubes are easy to handle and can be recycled further if needed. Densifiers are very effective and can handle a wide range of plastics. This is useful in minimising the quantity of plastic produced and thus contributing to environmental conservation.

The densifier is helpful in the recycling process of plastics as it eases the process and makes it more efficient.

Advanced Technology

Cutting Technology

The D-Series cutting mechanism processes most plastic films, tapes, yarns, wiry materials, fabrics, and bags. All materials are reduced to consistent particle sizes optimal for further processing.

Pneumatic Discharge

The discharge system incorporates pneumatic and screw-type mechanisms for rapid material evacuation from the processing drum, minimizing cycle times and maximizing productivity.

Control System

The control panel incorporates comprehensive safety features including single-phase prevention and overload protection systems, ensuring operational safety and equipment longevity.

Technical Specifications

| MODEL | PPM-800D | PPM-1000D | PPM-1200D | PPM-1200D | PPM-1500D | PPM-1500D |

|---|---|---|---|---|---|---|

| Main Motor (HP) | 60 | 75-120 | 150-180 | 220-270 | 340-420 | 540 |

| Batch Capacity KG. | 13-20 | 24-45 | 60-90 | 75-120 | 100-150 | 150-200 |

| Production Kg./Hr. | 80-100 | 170-200 | 400-600 | 700-1000 | 800-1200 | 1000-1600 |

Payment Options

Contact Information

Address

Plot No. 127, GIDC, Umbergaon-396171, Gujarat, India

Phone

+91 7046463391

info@panchal-plastic.com

sales@panchal-plastic.com