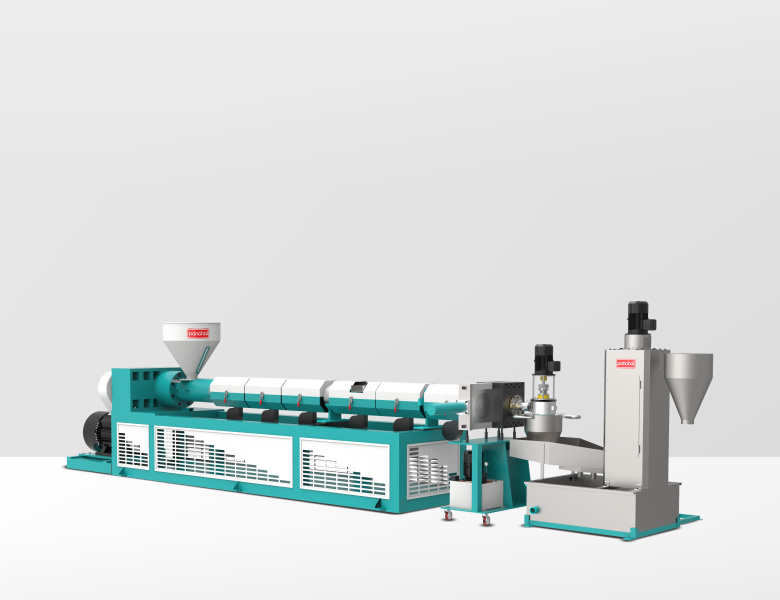

Extruder With Die-Face-Water Ring Type Machine

The Extruder With Die-Face-Water Ring Type Machine from Panchal Plastic Machinery offers a powerful solution for plastic recycling and compounding operations. Featuring an innovative water cooling system with high-pressure water jets that prevent overheating and ensure uniform, clean pellets.

Extruder With Die-Face-Water Ring Type Machine

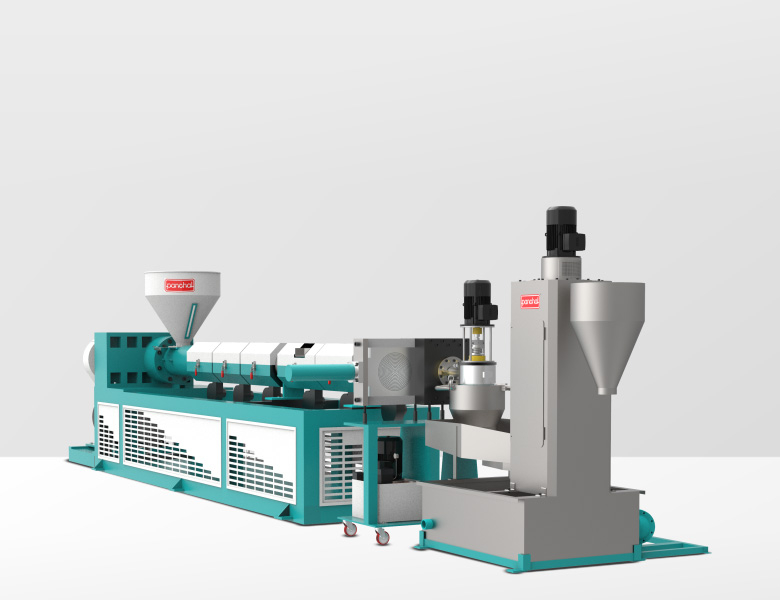

The Extruder With Die-Face-Water Ring Type Machine offers a powerful solution for plastic recycling and compounding operations. This extruder machine is versatile, capable of efficiently processing a wide range of plastic materials, including LDPE, HDPE, ABS, PS, and more.

A screw design guarantees gentle melting and produces pellets with minimum degradation. The minimal loss of physical characteristics allows one to use repelletized scrap at full value to virgin resin in many products. A high degree of process stability minimizes the influence of the operating personnel on pellet quality.

Simple access to wear parts reduces scheduled downtime to a minimum. Robust design, high-grade materials and top quality manufacturing in combination with the finest possible controls and proven electronics, guarantee a long service life.

Due to the excellent output rate in combination with low operating and energy costs the machine typically offers an extremely short payback period. We are pleased to calculate both your recycling operational costs per kg [lbs] and the payback period.

Key Features of Our Extruder With Die-Face-Water Ring Type

- Efficient Cooling System: Equipped with a water-cooling system that cools the pellets as they are being cut to enhance temperature control

- Smooth Feed Design: Capable of feeding in a smooth manner and ideal for recycling all forms of waste plastic materials

- Versatile Extrusion Line: Can process HM, HDPE, LDPE, LLDPE, and HIPS with production range of 100 kg/h to 300 kg/h

- Durable Construction: Nitrided screws and barrels of special alloy steel to prolong working life

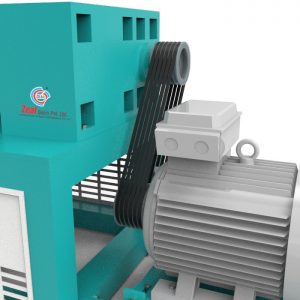

- Advanced Gearbox: Helical gearbox with built-in thrust bearing to enhance power transmission and gear life

- Hydraulic Filter Changer: Hydraulically operated filter changer for easy and seamless filter changes

- Precision Control: Melt pressure signal connected to the extruder AC inverter drive for better regulation

- Water Ring Die Face Cutter: System aids in appropriate cutting and cooling of pellets

- Stainless Steel Components: Water ring drum, granule cyclone system, and water collection tank made of stainless steel

- Effective Drying: Centrifugal dryer with high-speed rotation and heat to remove surface water

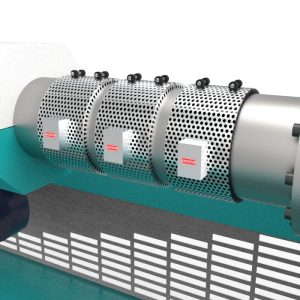

- High-Density Band Heaters: Regulate heat needed in extrusion process for consistency

Applications

The Extruder with Die Face Water Cooling Type is suitable for compounding, masterbatch manufacturing, and regranulation of plastics such as LD, HD, HM, and ABS.

- Compounding operations

- Masterbatch manufacturing

- Plastic regranulation

- LDPE recycling

- HDPE processing

- ABS material reprocessing

- Polystyrene recycling

- Industrial plastic waste management

The process of operation involves the extrusion of the polymer through the die plate, whereby the hot material is sliced into pellets by a rotating knife. These pellets are then directed towards a water-cooling chamber so as to ensure that they are well cooled.

The cooled pellets are then transferred to a centrifugal dryer, in which water on the surface is separated at high speed, and the heat remaining helps in drying the pellets. The dried pellets are then discharged into a conveying system or a container for storage or further use.

Advanced Technology

Extruder Die Face Water

The pelletizing systems of the DFW series are easy to operate. The pelletizing of PE, PP, PS, ABS and similar plastics is their field of application. High-pressure water jets prevent overheating and ensure uniform pellets.

Extruder Dryer

The pellets are cooled by the water and transferred directly from the cutting chamber to the centrifuge due to the high flow rate. The granules are then dried after being separated from the water through centrifugal force.

Control Panel

Control Panel consisting of all safety features related to machine with Single phase preventer, Over load preventer, and advanced monitoring systems for precise control of the extrusion process.

Ceramic Heating

Power saving ceramic heater with long life. Provides efficient and consistent heating for optimal material processing and energy savings.

Extruder Screw

Screw made of EN41B nitride steel duly gas nitride. Precision engineered for optimal material flow and mixing, ensuring consistent output quality.

Extruder Gearbox

Heavy duty helical gearbox with oil lubrication and water cooling for oil. Designed for high torque applications and continuous operation with minimal maintenance.

Technical Specifications

Standard Models

| MODEL | PPM-75DFW | PPM-90DFW | PPM-100DFW | PPM-120DFW | PPM-140DFW |

|---|---|---|---|---|---|

| Screw Diameter (mm) | 75 | 90 | 100 | 120 | 140 |

| L/D Ratio | 26:1 | 26:1 | 26:1 | 26:1 | 26:1 |

| Heating Load (kW) | 18 | 22 | 26 | 30 | 38 |

| Main Motor (HP) | 25 | 30 | 40 | 50 | 60 |

| Screen Changer (HP) | 3 | 3 | 5 | 5 | 5 |

| Die Face Drive (HP) | 2 | 2 | 3 | 3 | 3 |

| Water Pump (HP) | 2 | 2 | 2 | 2 | 2 |

| Spin Dryer (HP) | 3 | 3 | 3 | 5 | 5 |

| Production (Kg/Hr.) | 70-100 | 100-150 | 110-180 | 150-250 | 200-350 |

High Performance Models

| MODEL | PPM-75DFWV | PPM-90DFWV | PPM-100DFWV | PPM-120DFWV | PPM-150DFWV | PPM-160DFWV | PPM-180DFWV |

|---|---|---|---|---|---|---|---|

| Screw Diameter (mm) | 75 | 90 | 100 | 120 | 150 | 160 | 180 |

| Main Motor (kw) | 37 | 45/55 | 55/75 | 110/160 | 160/200 | 200/315 | 355/400 |

| L/D Ratio | 35:1 | 35:1 | 35:1 | 35:1 | 35:1 | 35:1 | 35:1 |

| Heating Load (kW) | 25 | 30 | 35 | 50 | 65 | 78 | 110 |

| Production (KG/HR.) | 100-150 | 180-250 | 220-300 | 300-450 | 300-450 | 750-1000 | 900-1200 |

Payment Options

Contact Information

Address

Plot No. 127, GIDC, Umbergaon-396171, Gujarat, India

Phone

+91 7046463391

info@panchal-plastic.com

sales@panchal-plastic.com