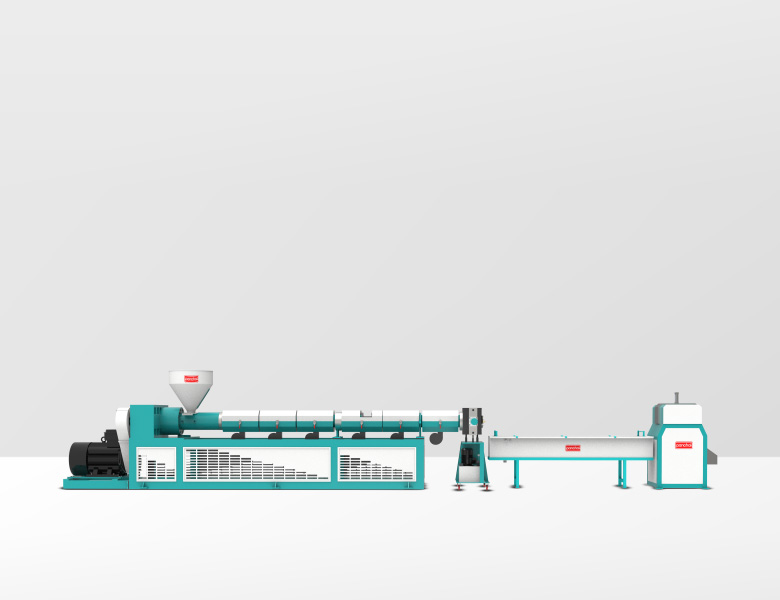

Extruder With Strand Pelletizer Machine

The Extruder With Strand Pelletizer Machine is an innovative and high-performance solution designed for efficient plastic granulation, recycling, and reuse. Built to last with premium materials, it transforms various plastics into high-quality pellets with consistent output and optimal performance.

Extruder With Strand Pelletizer Machine

The Extruder With Strand Pelletizer Machine from Panchal Plastic Machinery Pvt. Ltd. represents a significant advancement in plastic processing technology. This innovative equipment converts raw plastic materials into uniform strands, which are then precisely cut into high-quality pellets, dramatically improving production efficiency and product consistency.

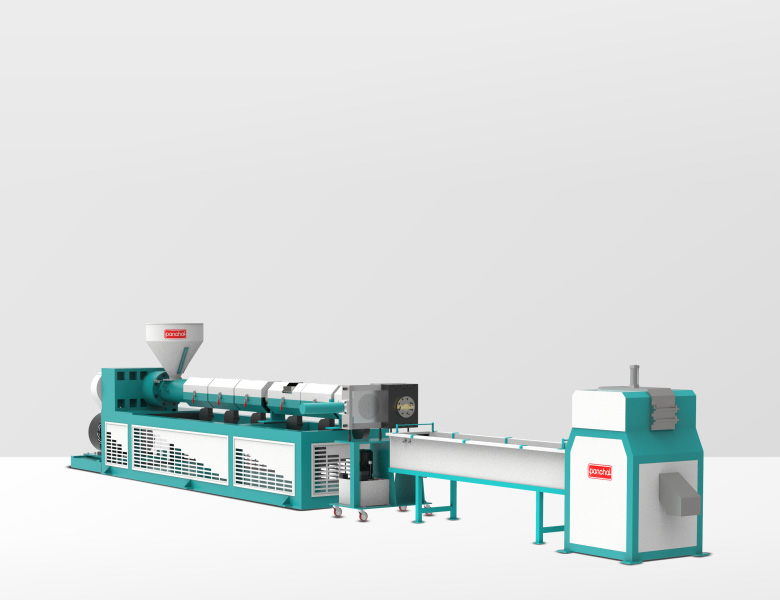

As a premier manufacturer of extrusion systems, we've engineered this machine to address the most demanding production requirements with exceptional robustness and consistent output. The intuitive operational design enables seamless integration into facilities of any scale, from modest recycling operations to large industrial complexes.

The operational principle involves feeding plastic materials into the extruder where they are melted, homogenized, and forced through a die to form continuous strands. These strands are then cooled in a water bath and fed into the pelletizer where rotating knives cut them into uniform pellets. The entire process is precisely controlled to ensure consistent pellet size and quality.

This transformation process converts plastic materials into valuable raw pellets, justifying the investment through operational efficiencies and cost savings in material handling. By adopting this advanced technology, businesses enhance their production capabilities while supporting sustainable manufacturing practices.

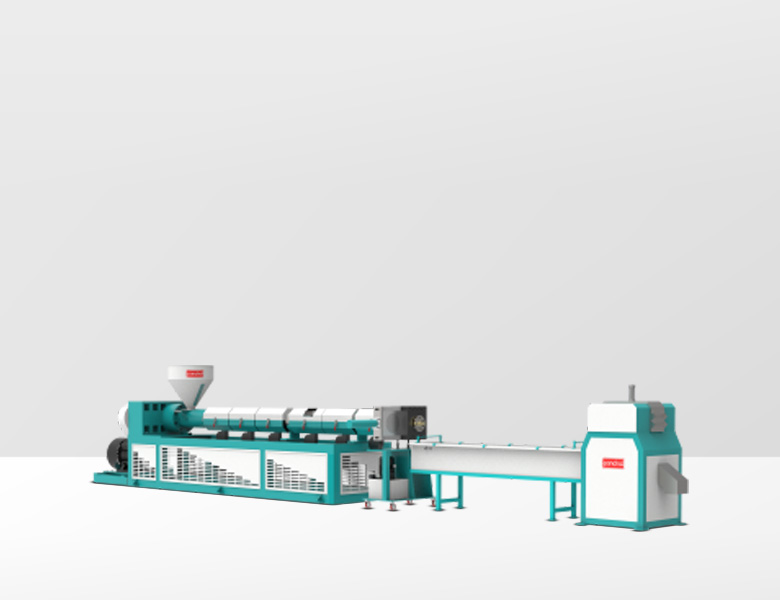

Key Features of Our Extruder With Strand Pelletizer

- Single Screw Design for simple pelletizing operations

- Sturdy Construction with strong steel welded frame

- Helical Gearbox Unit for high accuracy and reliability

- Nitriding Steel Cylinder and Screw for enhanced wear resistance

- Precise Temperature Regulation with PID control system

- Efficient Screen Changer for uninterrupted operation

- Comprehensive Cooling System with stainless steel water tank

- Customizable L/D Ratio up to 35:1 for material versatility

Applications

The Extruder With Strand Pelletizer serves various plastic processing applications, suitable for:

- LDPE pelletizing and recycling

- HDPE processing and granulation

- PP (Polypropylene) material processing

- PVC compounding and pelletizing

- PET recycling and reprocessing

- HIPS (High Impact Polystyrene) production

- PC (Polycarbonate) processing

- ABS (Acrylonitrile Butadiene Styrene) compounding

This equipment processes all categories of plastic materials, converting them into uniform pellets suitable for injection molding, extrusion, and other manufacturing processes. Particularly effective for recycling operations and compound production, it represents an essential tool for modern plastic processing facilities.

Implementation of our extrusion technology enables businesses to enhance production efficiency, minimize material waste, and develop cost-effective manufacturing solutions while maintaining consistent product quality.

Advanced Technology

High-Quality Extruder Screw

The screw is made of EN41B nitride steel, duly gas nitrided for exceptional wear resistance and durability. This precision-engineered component ensures efficient melting, mixing, and conveying of plastic materials.

Heavy Duty Gearbox

The internal asynchronous helical gearbox with case-hardened and hardened gears made of high-quality materials ensures reliable power transmission. Features oil lubrication and water cooling for optimal performance and longevity.

Technical Specifications

| MODEL | PPM-75E | PPM-90E | PPM-100E | PPM-120E | PPM-140E | PPM-150E | PPM-160E | PPM-180E |

|---|---|---|---|---|---|---|---|---|

| Screw Diameter (mm) | 75 | 90 | 100 | 120 | 140 | 150 | 160 | 180 |

| Main Motor (HP) | 20 | 30 | 40 | 60 | 75 | 120 | 150 | 215 |

| L/D Ratio | 26:1 | 26:1 | 26:1 | 26:1 | 26:1 | 26:1 | 26:1 | 26:1 |

| Heating Load (kW) | 18 | 22 | 28 | 32 | 36 | 55 | 65 | 82 |

| Pelletizer Size (In.) | 4 | 6 | 6 | 8 | 8 | 10 | 10 | 12 |

| Pelletizer Motor (HP) | 2 | 3 | 3 | 5 | 5 | 7.5 | 10 | 15 |

| Production (KG/HR) | 60-80 | 90-120 | 100-150 | 200-250 | 300-350 | 350-400 | 400-500 | 600-700 |

High Performance Models

| MODEL | PPM-75EV | PPM-90EV | PPM-100EV | PPM-120EV | PPM-150EV | PPM-160EV | PPM-180EV |

|---|---|---|---|---|---|---|---|

| Screw Diameter (mm) | 75 | 90 | 100 | 120 | 150 | 160 | 180 |

| Main Motor (kw) | 37 | 45/55 | 55/75 | 110/160 | 160/200 | 200/315 | 355/400 |

| L/D Ratio | 35:1 | 35:1 | 35:1 | 35:1 | 35:1 | 35:1 | 35:1 |

| Heating Load (kW) | 25 | 30 | 35 | 50 | 65 | 78 | 110 |

| Production (KG/HR) | 100-150 | 180-250 | 220-300 | 300-450 | 300-450 | 750-1000 | 900-1200 |

Payment Options

Contact Information

Address

Plot No. 127, GIDC, Umbergaon-396171, Gujarat, India

Phone

+91 7046463391

info@panchal-plastic.com

sales@panchal-plastic.com