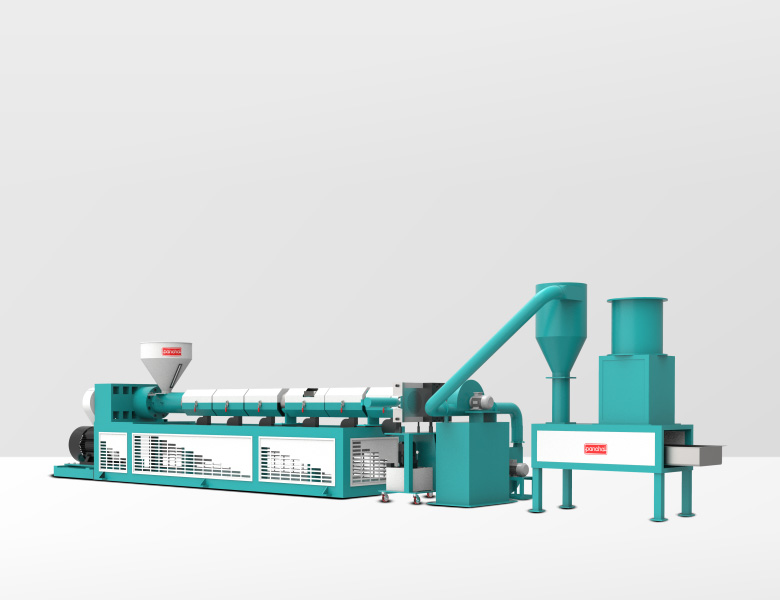

Extruder With Die-Face-Air-Cooling Machine

Panchal Plastic Machinery's Extruder with Die-Face-AIR Cooling Type Machine offers an innovative solution for re-granulating plastic materials. Utilizing high-pressure air jets to cool the die face, it prevents plastic from melting or sticking, ensuring streamlined processing and high-quality output.

Extruder With Die-Face-Air-Cooling Machine

Air Cooling Die Face pelletizing is used for moistureless high quality pellets. The Extruder with Die-Face-AIR Cooling Type Machine utilizes a unique system of high-pressure air jets to cool the die face, preventing plastic from melting or sticking to the surface.

This advanced technology ensures streamlined processing, maintaining high-quality standards while producing cleaner, more consistent products. The versatility of this machine allows it to handle a wide range of plastic materials, including LDPE, HM, LLDPE, PVC, Lubra, compounds, masterbatch, and fillers.

Specially designed for easy and economical operations with possibility to change the size of granule. No need of water for cooling, producing moisture free granules with perfect virgin-type quality. Requires less space compared to traditional systems.

A screw design guarantees gentle melting and produces pellets with minimum degradation. The minimal loss of physical characteristics allows one to use repelletized scrap at full value to virgin resin in many products. A high degree of process stability minimizes the influence of the operating personnel on pellet quality.

Key Features of Our Extruder With Die-Face-Air-Cooling

- Durability: Made of quality and strong materials that enable the building to withstand all the testable years

- Hassle-Free Performance: Designed to operate with little or no chances of developing faults or stopping suddenly

- Ease of Operation: Durability and reliability ensure that the device will be easy to handle and control, as well as easy to maintain

- Quality Granules: This helps in achieving the quality of the granules that can be produced at a certain level of production

- Electro Welded Steel Base: Helps to determine the sound foundation on which structures can be developed

- Helical Gearbox Unit: Comprises case-hardened and ground profiles for the best performance

- Simple access to wear parts reduces scheduled downtime to a minimum

- Robust design, high-grade materials and top quality manufacturing guarantee a long service life

Applications

The Extruder with Die Face Air Cooling Type is suitable for processing various types of plastics. In the operation, after the polymer has been extruded through the die plate, a rotating knife slices the hot material into pellets.

- LDPE materials

- HM plastics

- LLDPE films

- PVC compounds

- Lubra materials

- Masterbatch production

- Filler materials

- Plastic compounds

These pellets are cooled through an air cyclone system and then discharged into a conveying system or container. This process helps in the proper and efficient regranulation of the plastic material, making it appropriate for industries that deal with the recycling of plastics.

Conclusively, the machine is durable, easy to use, performs optimally, and thus can be of great value to any plastic processing plant.

Advanced Technology

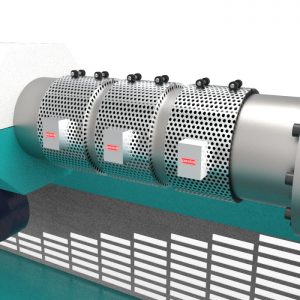

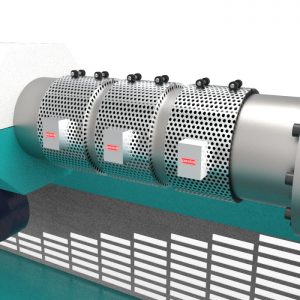

Extruder Ceramic Heating

Power saving ceramic heater and long life. Efficient heating system that ensures consistent temperature control throughout the extrusion process for optimal material processing.

Extruder Screw

Screw made of EN41B nitride steel duly gas nitride. Precision engineered for optimal material flow and mixing, ensuring consistent output quality and reduced energy consumption.

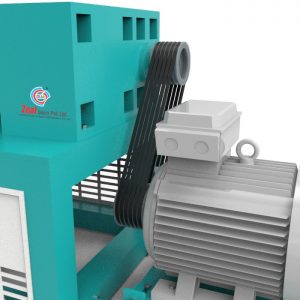

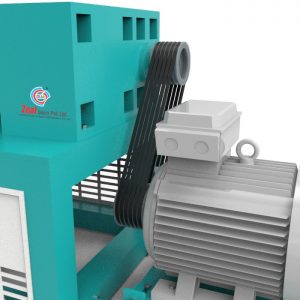

Extruder Gearbox

Heavy duty helical gearbox with oil lubrication and water cooling for oil. Designed for high torque applications and continuous operation with minimal maintenance requirements.

Die Face Air Cutting

The air pelletizer was designed to use air to cool and transport pellets and thus eliminate any need to dry the pellets. High-pressure air jets precisely cool the die face for optimal pellet formation.

Technical Specifications

| MODEL | PPM-50DFA | PPM-65DFA | PPM-75DFA | PPM-90DFA | PPM-100DFA |

|---|---|---|---|---|---|

| Screw Diameter (mm) | 50 | 65 | 75 | 90 | 100 |

| L/D Ratio | 26:1 | 26:1 | 26:1 | 26:1 | 26:1 |

| Heating Load (kW) | 10 | 12 | 18 | 22 | 26 |

| Main Motor (HP) | 15 | 20 | 25 | 30 | 40 |

| Screen Changer (HP) | 3 | 3 | 3 | 3 | 5 |

| Die Face Drive (HP) | 1 | 1 | 2 | 2 | 2 |

| Cooling Blower (HP) | 2 | 2 | 2 | 2 | 2 |

| Cyclone Blower (HP) | 1 | 1 | 1 | 2 | 2 |

| Production (Kg/Hr.) | 20-40 | 30-50 | 50-80 | 90-120 | 110-180 |

Payment Options

Contact Information

Address

Plot No. 127, GIDC, Umbergaon-396171, Gujarat, India

Phone

+91 7046463391

info@panchal-plastic.com

sales@panchal-plastic.com