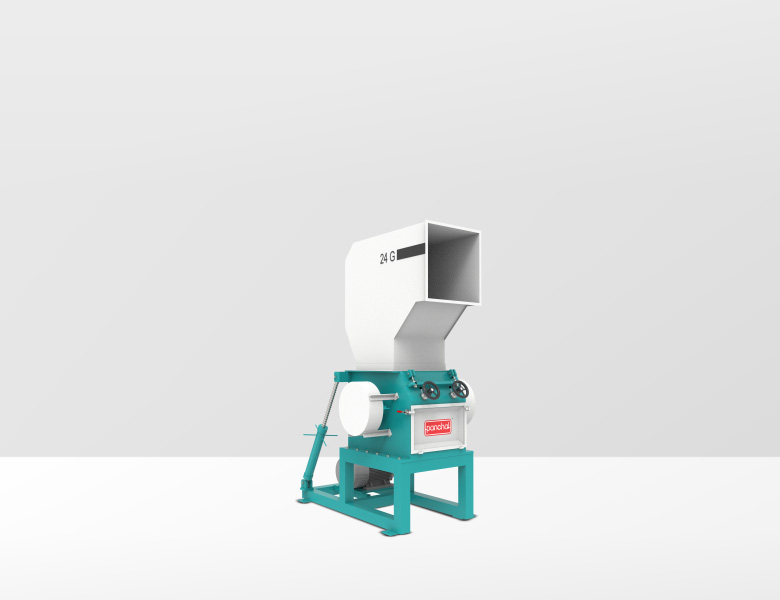

Film & Sheet Grinders Series Machine

The Film and Sheet Series Machine by Panchal Plastic Machinery Pvt. Ltd. is a versatile and efficient solution for processing waste plastic film and sheet rolls. Designed to handle rolls of varying sizes and thicknesses with precision and ease, it ensures high-quality granulation results.

Film & Sheet Grinders Series Machine

The Film and Sheet Series Machine by Panchal Plastic Machinery Pvt. Ltd. is a versatile and efficient solution for processing waste plastic film and sheet rolls. As a trusted Film and Sheet Series Machine Manufacturer, Panchal offers innovative systems designed to handle rolls of varying sizes and thicknesses with precision and ease.

Larger rolls, such as those in the 18" to 24" series and beyond, can be directly fed into Panchal granulators. These granulators feature durable components and a consistent cutting circle, ensuring effortless slicing through thick films and sheets. For rolls of varying widths, the Panchal roll-feed system offers an alternative, enabling seamless unwinding and feeding into a suitable granulator.

Panchal's granulators stand out for their advanced cutter-house, rotor, and knife designs, which guarantee clean and precise cutting, even for thin films. This approach ensures high-quality granulation results across different roll sizes. The adaptability of the Film and Sheet Series Machine makes it an essential tool for industries looking to optimize their plastic waste recycling processes.

By combining efficiency, reliability, and innovation, Panchal Plastic Machinery Pvt. Ltd. provides an unmatched solution to address the diverse needs of plastic recycling businesses. Choose the Film and Sheet Series Machine to streamline your recycling operations and achieve exceptional results in managing plastic waste.

Key Design Features:

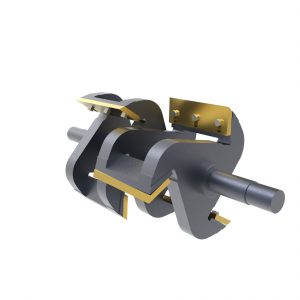

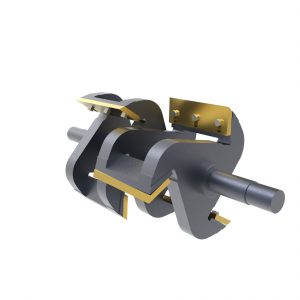

- Specialized rotor design tailored for thin film and sheet materials

- Optional water cooling on body for added efficiency

- Curved backwall maximizes space for large volume parts

- Specially developed 3rd knives and blades with deflector wedges

- Strong welded steel construction ensures durability

- D2 steel blades ensure longevity

- Heavy-duty bearings and housing outside the cutting chamber

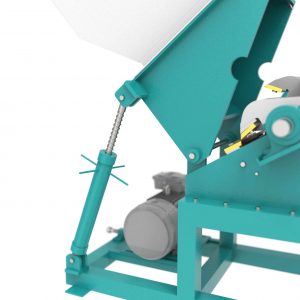

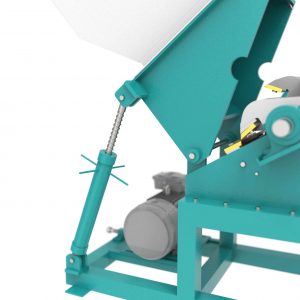

- Optional tilt-back hopper with auger (hydraulic if preferred)

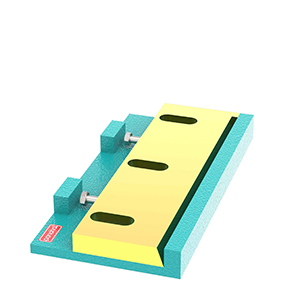

- Jig fixture for convenient knife adjustments outside the system

- Safety interlocks and dropdown screen cradle at the front

Key Features of Our Film & Sheet Grinders Series

- Robust Construction: Constructed to endure, this grinder boasts a strong build that resists wear and tear even under the harshest industrial use.

- Feeding Options: You can load materials manually or use a robotic system for automatic feeding, adding efficiency to the workflow.

- Roller Feeder for Films: Specially designed for plastic films, the roller feeder ensures these materials are fed smoothly for consistent grinding.

- High Output Range: Whether the job is small or large, this machine delivers, with a grinding capacity ranging from 20 to 1000 kg/hr.

- Heavy Rotor: The hefty rotor is key to its powerful grinding capability, ensuring quick and effective material reduction.

- Soundproof Cabinet Option: For quieter operation, you can choose models equipped with a soundproof cabinet, ideal for reducing noise in sensitive environments.

- Advanced Cutting Mechanism: Precision rotor and knives with staggered and double cross-cutting configurations, along with robust bearings, ensure meticulous grinding. Includes a sophisticated suction system with a fan and cyclone for efficient waste disposal.

Applications

The Film and Sheet Grinder Machine is an efficient solution for processing waste plastic film and sheet rolls. With two operating methods, the machine ensures that recycling is done without any problems, meeting the different needs of recycling in the best way possible.

For large rolls, such as those in the 18" to 24" series and beyond, our granulators offer easy feed. The solid parts and unvarying cutting circle make it easy to slice through the sheet and thick film parts, ensuring effective processing. Instead, our roll-feed system allows for the continual unwinding and feeding into the suitable granulator for rolls with different widths, offering seamless operation and proper utilisation of resources.

With an excellent cutter-house, rotor, and knife design, our granulators achieve clean and precise cutting, even with thin films, ensuring great-quality granulation results. Our film and sheet grinder machines give you ease in size, versatility, and consistency in obtaining high-quality granulated materials.

Experience the efficiency and flexibility of our machine for plastic waste management today!

Advanced Technology

Grinder Rotor

Provides full and easy access to the complete interior of the cutting chamber including the granule bin and the screen. This gives unmatched access to both rotating and fixed knives when serviced. And, when you change material and/or colour, you get complete control of the cleaning – Visually clean inspection.

Front Screen Cradle

Provides full access to the interior of the cutter house. Cleaning and maintenance with full visibility and accessibility.

Manual Jack

Provides a secure and efficient opening of the granulator for easy maintenance and cleaning operations.

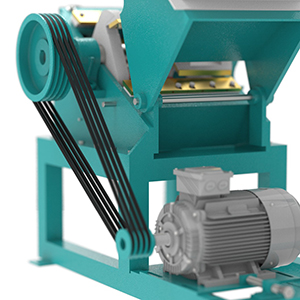

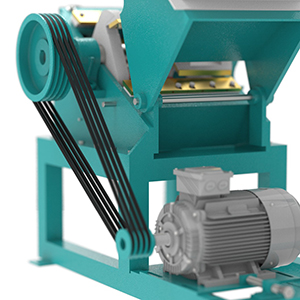

V-Belt Drive

Provides powerful and energy-saving granulation at the same time, ensuring efficient operation with reduced power consumption.

Cross Body Opening

Provides full access to the interior of the cutter house. Cleaning and maintenance with full visibility and accessibility.

Jig Fixture

Rotor and fixed knives/blades are adjusted outside of the granulator by using jig fixture, ensuring precise alignment and easy maintenance.

Technical Specifications

| MODEL | PPM-12GF | PPM-15GF | PPM-18GF | PPM-24GF | PPM-30GF | PPM-40GF |

|---|---|---|---|---|---|---|

| Main Motor (HP) | 5 | 10 | 15 | 30 | 50 | 75 |

| Cutterhouse (Inches) | 12x12 | 15x15 | 18x18 | 24x22 | 30x26 | 40x36 |

| Production (KG/HR) | 50-75 | 75-100 | 100-150 | 200-250 | 350-400 | 500-600 |

| Screen hole (mm) | 8/10/12 | 8/10/12 | 8/10/12 | 8/10/12 | 8/10/12 | 8/10/12 |

| Rotor Type | Open/Staggerd | Open/Staggerd | Open/Staggerd | Open/Staggerd | Open/Staggerd | Open/Staggerd |

| Blower with cyclone* | 1HP | 2HP | 2HP | 3HP | 5HP | 7.5HP |

Payment Options

Contact Information

Address

Plot No. 127, GIDC, Umbergaon-396171, Gujarat, India

Phone

+91 7046463391

info@panchal-plastic.com

sales@panchal-plastic.com