Lumps Grinder Series Machine

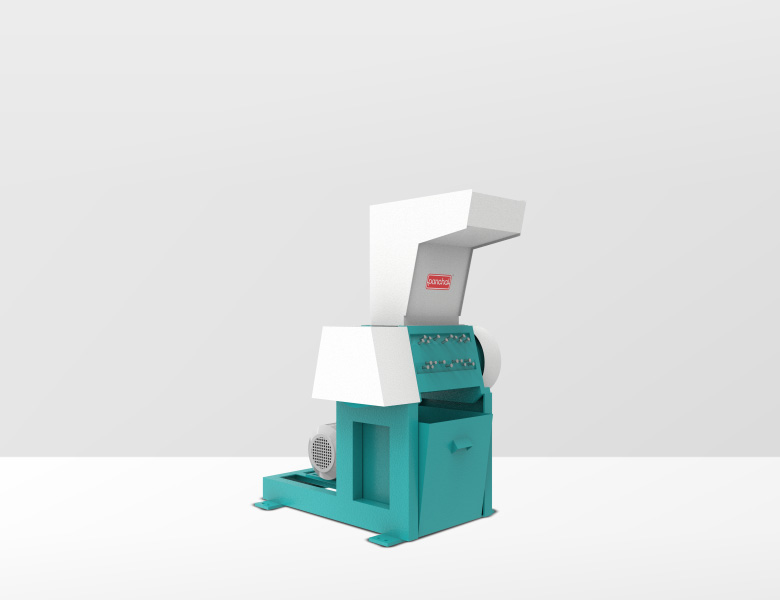

The LUMPS series plastic lumps grinder is a powerful solution designed for efficiently processing thick-walled moldings, sheets, sprue cakes, pipes, and profiles. Equipped with a robust rotor made from a single piece of metal, it handles large and voluminous plastic lumps with ease.

Lumps Grinder Series Machine

Panchal Plastic Machinery Pvt. Ltd. offers the LUMPS series plastic lumps grinder, a powerful solution designed for efficiently processing thick-walled moldings, sheets, sprue cakes, pipes, and profiles. As a leading Lumps Grinder Machine Manufacturer, Panchal ensures that each grinder is equipped with a robust rotor made from a single piece of metal, making it capable of handling large and voluminous plastic lumps with ease.

This innovative design is optimized for high-efficiency granulation, ensuring smooth, one-step processing of even the largest plastic lumps. The LUMPS series grinder is tailored to meet the specific needs of production start-ups, where quick and precise material reduction is essential.

With a solid, massive rotor and a robust cutting chamber, this system ensures durability and reliability. Equipped with D2 steel knives, it guarantees efficient cutting performance. The drop-down screen cradle enhances user convenience, while the heavy hopper facilitates easy material loading.

Operating at low RPM with high torque, it offers powerful performance with minimal energy consumption. Safety interlocks provide added security during operation, ensuring a safe working environment. Overall, it delivers high performance while minimizing energy requirements, making it an efficient and effective solution for various applications.

Key Features of Our Lumps Grinder Series

- Enhanced Stability: The machine boasts exceptional stability, ensuring consistent and precise granulation of diverse plastic materials.

- Robust Rotor: Equipped with a solid metal rotor, the grinder/granulator achieves a high moment of gyration, facilitating effective granulation.

- Versatile Processing: Capable of granulating voluminous and large-surface automotive parts like bumpers, dismounted parts from old cars, plastic tanks, door interior cladding, and more.

- Single-Stage Granulation: With a specially designed single-stage granulation unit, even large chunks from the initial production stages can be processed, enhancing efficiency and reducing processing time.

- Wide Material Compatibility: Ideal for granulating various materials, including lumps, pipes, and profiles, offering flexibility in recycling different types of plastics.

- D2 Steel Knives: Equipped with high-quality D2 steel knives for efficient cutting performance and durability.

- Low RPM with High Torque: Operates at low RPM with high torque for powerful performance with minimal energy consumption.

- Safety Interlocks: Provides added security during operation, ensuring a safe working environment.

Applications

The LUMPS series grinder serves various recycling processes, suitable for processing:

- Thick-walled moldings and parts

- Plastic sheets and panels

- Sprue cakes and runners

- Plastic pipes and profiles

- Automotive parts (bumpers, tanks)

- Door interior cladding

- Large plastic lumps and purgings

- Industrial plastic scrap

This equipment processes all categories of plastic lumps and thick-walled materials, converting them into uniform granules, thereby reducing waste volume and conserving natural resources. Particularly effective for large automotive parts and diverse industrial plastic scraps, it represents an essential tool for modern recycling operations.

Implementation of our lumps grinding technology enables businesses to enhance recycling efficiency, minimize environmental impact, and develop cost-effective waste management solutions.

Advanced Technology

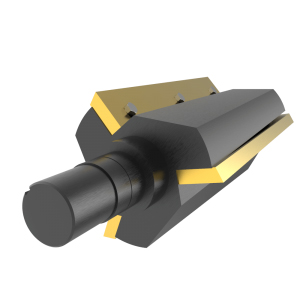

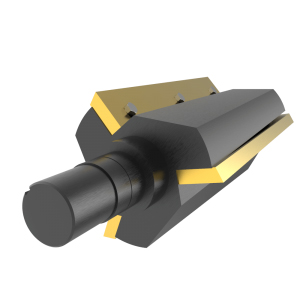

Solid Rotor Technology

The solid rotor enables more blade surface to quickly reduce lumps/purge into granulate with less dust and fines than traditional blade rotor designs. Heavy duty solid rotor designed specifically for thick wall products and small lumps and purge.

Control System

The control panel incorporates comprehensive safety features including single-phase prevention and overload protection systems, ensuring operational safety and equipment longevity. User-friendly interface allows for easy operation and monitoring.

Technical Specifications

| MODEL | PPM-15LG | PPM-18LG | PPM-24LG | PPM-30LG | PPM-40LG |

|---|---|---|---|---|---|

| Main Motor (kW) | 7.5 | 15 | 22 | 55 | 90 |

| Cutter House Opening (mm) | 375 × 200 | 450 × 200 | 600 × 200 | 750 × 250 | 1000 × 250 |

| Rotating Blades | 3 | 3 | 3 | 3 | 3 |

| Fix Blades | 4 | 4 | 4 | 4 | 4 |

| Production (Kg./Hr.) | 100-150 | 200-300 | 300-400 | 700-800 | 1300-1500 |

| Screen Hole (mm) | 8/10/12 | 8/10/12 | 8/10/12 | 8/10/12 | 8/10/12 |

| Rotor Type | Solid | Solid | Solid | Solid | Solid |

Payment Options

Contact Information

Address

Plot No. 127, GIDC, Umbergaon-396171, Gujarat, India

Phone

+91 7046463391

info@panchal-plastic.com

sales@panchal-plastic.com