Pipe and Profile Grinder Series Machine

The Pipe and Profile Grinder Series Machine by Panchal Plastic Machinery Pvt. Ltd. is a cutting-edge solution for recycling plastic pipes and profiles. We offer two unique designs tailored to meet diverse recycling needs: side feeding and front tilt feeding.

Pipe and Profile Grinder Series Machine

The Pipe and Profile Grinder Series Machine by Panchal Plastic Machinery Pvt. Ltd. is a cutting-edge solution for recycling plastic pipes and profiles. As a trusted Pipe and Profile Grinder Series Machine Manufacturer, we offer two unique designs tailored to meet diverse recycling needs: side feeding and front tilt feeding.

Our versatile range includes specialized HDPE grinders, PVC grinders, and the highly adaptable PVS grinder machine. These machines are designed to handle various sizes of pipes and profiles with unmatched efficiency. For smaller dimensions, the 18", 24", and 30"-Series machines provide precise and reliable grinding, while the robust 40"-Series and 48"-Series machines are engineered for larger pipes and profiles.

To enhance functionality, these machines can be equipped with special in-feed hoppers tailored to accommodate specific processing requirements. In addition to this, our Panchal Shredder/Granulator features advanced automatic feeding control, making it an ideal choice for recycling large pipes and profiles.

Combining innovative design and high performance, these machines streamline plastic waste management while promoting sustainable practices. Designed for durability and precision, the Pipe and Profile Grinder Series Machine delivers efficient, eco-friendly solutions to meet the demands of modern recycling facilities.

Key Features of Our Pipe and Profile Grinder Series

- Front side feeding model for small and light pipe and profiles

- Side tangible feeding model for large diameter and long size pipe and profiles

- Specially developed deflector wedge

- Strong Welded Steel construction

- D2 Steel Blades/Knives

- Heavy duty bearings out of cutting chamber

- Tilt Back Hopper

- Knives are adjusted outside of the machine

- Safety interlock Features

- Robust Construction: Built tough for enduring reliability, ensuring quality performance even with challenging materials.

- Feeding Options: This machine can be either operated manually or via a robot, which in turn helps in providing flexibility to the feeding of the materials for grinding.

- High Output Range: Adjustable from 20 to 1000 kg/hr, catering to diverse production needs with flexibility.

- Versatile Models: Different models give the option of using them all in processing applications that need different scales and types of equipment.

- Efficient Cutting Mechanism: Utilizes staggered and double cross-cutting rotors, allowing continuous operation with pre-adjusted rotor and bed knives to prevent motor overload.

- Versatile Recycling: Not restricted to cold melt granulation, these mills and granulators excel in hot melt granulation, enhancing versatility in recycling operations.

- Advanced Material Handling: Equipped with heavy-duty bearings and a suction system including a flow-through fan and cyclone, ensuring reliable performance and effective waste management during operation.

Applications

The pipe grinder is a machine made for the easy recycling of all kinds of plastic pipes and profiles. Be it HDPE, PVC, or PVS, our grinder can grind everything. We have a side feeding design and a front tilt feeding design available for the clients as per their convenience.

- HDPE pipes and profiles

- PVC pipes and profiles

- PVS pipes and profiles

- Plastic pipe recycling

- Profile recycling operations

- Industrial plastic waste management

- Construction material recycling

- Plastic manufacturing scrap processing

Available in multipurpose and dedicated HDPE grinders, PVC grinders, and one for PVS grinder machines, our range is sure to offer the right solution for your needs. We have 18", 24", and 30"-Series machines for smaller pipes and profiles, while our 40"-Series machines have been made considering the larger ones.

Our 40"-Series and 48"-Series machines can also be equipped with special pipe/profile in-feed hoppers. For large pipes and profiles, we have an advanced Panchal shredder/granulator with automatic feeding control that assures efficient and sustainable recycling solutions. Get our pipe grinder and recycle plastic pipes and profiles without the least hassles for a cleaner and greener environment.

Advanced Technology

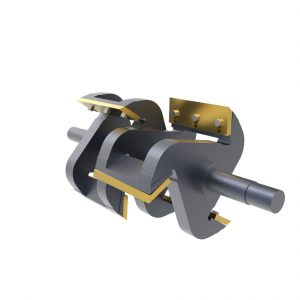

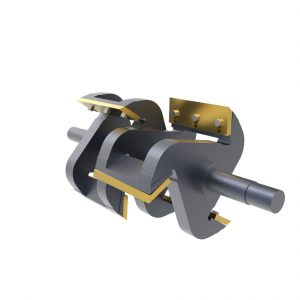

Pipe Grinder Rotor

Provides full and easy access to the complete interior of the cutting chamber including the granule bin and the screen. This gives unmatched access to both rotating and fixed knives when serviced. And, when you change material and/or colour, you get complete control of the cleaning – Visually clean inspection.

Front Screen Cradle

Provides full access to the interior of the cutter house. Cleaning and maintenance with full visibility and accessibility. Ensures easy maintenance and thorough cleaning between material changes.

V-Belt Drive System

Provides powerful and energy-saving granulation at the same time. The efficient drive system ensures optimal power transmission while reducing energy consumption and maintenance requirements.

Cross Body Opening

Provides full access to the interior of the cutter house. Cleaning and maintenance with full visibility and accessibility. This design feature significantly reduces downtime during maintenance operations.

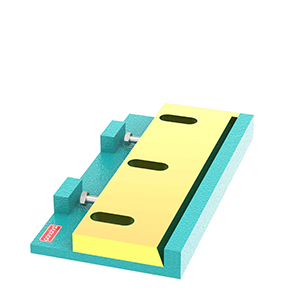

Jig Fixture System

Rotor and fixed knives/blades are adjusted outside of the granulator by using jig fixture. This innovative system ensures precise blade alignment and reduces maintenance time significantly.

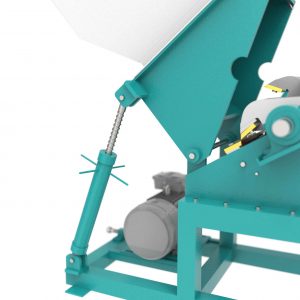

Manual Jack System

Provides a secure and efficient opening of the granulator. The manual jack system ensures safe and controlled access to the cutting chamber for maintenance and cleaning operations.

Technical Specifications

| MODEL | PPM-60/50GPP | PPM-55/70GPP | PPM-55/100GPP | PPM-70/140GPP |

|---|---|---|---|---|

| Rotor Diameter (mm) | 600 | 550 | 550 | 700 |

| Rotor Width (mm) | 500 | 700 | 1000 | 1400 |

| Motor Power (HP) | 60 | 75 | 100 | 120 |

| Rotating Blades/Knives | 5 | 5/7 | 5/7 | 5/7 |

| Fixed Blades/Knives | 2 | 2 | 2 | 2 |

| Screen Size (mm) | 8/10/12 | 8/10/12 | 8/10/12 | 8/10/12 |

| Feeding Size (mm) | 400×500 | 300×700 | 300×1000 | 300×1400 |

| Weight of Machine (kg) | 4000 | 5000 | 5000 | 8000 |

Payment Options

Contact Information

Address

Plot No. 127, GIDC, Umbergaon-396171, Gujarat, India

Phone

+91 7046463391

info@panchal-plastic.com

sales@panchal-plastic.com