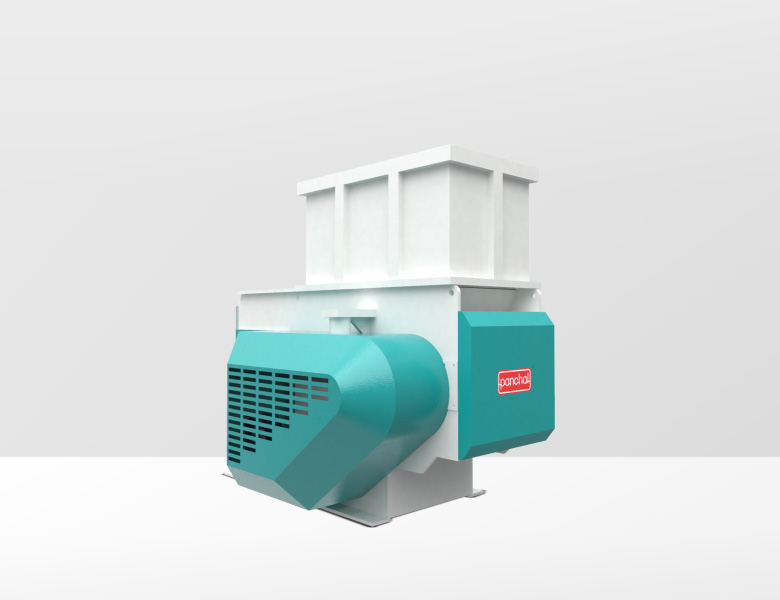

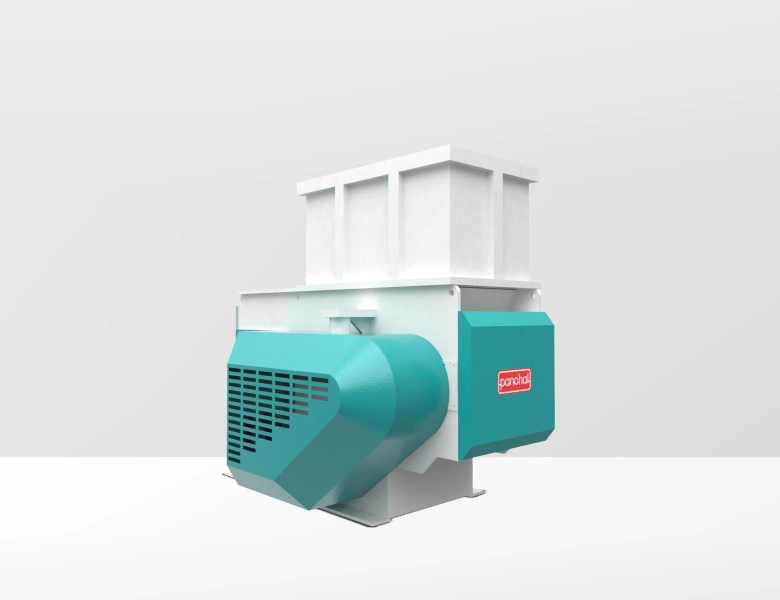

Single Shaft Shredder Machine

Our single shaft shredder was originally designed for efficient plastic shredding, but its capabilities extend to various materials, including wood off-cuts and textiles. What sets this mid-range single-shaft shredder apart is its remarkable throughput rate, achieved through a combination of the rotor and swing-pusher in-feed system.

Single Shaft Shredder Machine

Our single shaft shredder was originally designed for efficient plastic shredding, but its capabilities extend to various materials, including wood off-cuts and textiles. What sets this mid-range single-shaft shredder apart is its remarkable throughput rate, a feat achieved through a combination of the rotor and swing-pusher in-feed system, purposefully designed to guide materials into the machine.

Whether it's plastic recycling, industrial material shredding, or waste reduction, our single shaft shredder is a reliable choice. At Panchal Plastic, we're committed to providing high-quality recycling equipment that not only meets but exceeds your expectations.

Designed for plastics

The Single Shaft Shredder has been designed exclusively for efficient recycling of polymer materials.

Energy saving

A Single Shaft Shredder followed by a grinder/granulator is a solution that is very energy effective. Compared to a solution with a single large grinder/granulator for the job, the Single Shaft Shredder in combination with an optimized grinder/granulator do the job much more effectively.

V-CUT cutting technology

The unique V-CUT Technology is a combination of V-knife cutting angle, cutting speed and sequential cutting. It provides the best shredding solution for plastic materials. V-CUT provides a sheer and smooth cut with low stress and therefore requires less motor power.

Hydraulic PUSHing system

The pneumatic PUSH-system is auto-regulating, efficiently absorbing vibrations and mechanical stress that occur in tough applications. The special hopper design allows material to feed directly into the rotor.

Special gear box design

The Single Shaft Shredder design contains no compromises. Its unique cutting technology together with a Special gearbox requires lower motor power for the job, minimizing energy consumption.

Easy cleaning/access

The design puts handling in focus. Cleaning the machine for new materials or colors is easy. Just remove a front side plate, and you have quick access to the machine's interior.

Screenless operation

As the material is cut into uniform pieces, the Single Shaft Shredder operates with & without a screen, although screens can be installed as an option when smaller chip sizes are required.

Easy maintenance

The front opening makes it possible to access the rotor of the machine fast and easily. All knives, rotating and fixed are easy accessible. The rotating knives are reversible and are of cassette type, simplifying maintenance.

Key Features of Our Single Shaft Shredder

- Solid Construction: The sturdy hull is crafted from high-quality thick plate materials, ensuring durability and resilience during operation.

- Heavy Rotor: Equipped with a high-performance cutter designed to minimise energy consumption, it is efficient for various scrap materials.

- Special Steel Blades: Features durable steel blades for easy cutting and long-lasting performance.

- Heavy-Duty Gearbox: Incorporates a robust gearbox capable of withstanding the demanding shredding environment.

- Low Maintenance: Boasts high reliability with minimal maintenance requirements, reducing downtime for uninterrupted operation.

- PLC Control Panel: Equipped with a user-friendly PLC-based control panel for convenient and efficient operation.

- Energy-efficient operation lowers running expenses

- Compact footprint maximizes facility space utilization

Applications

The single-shaft shredder is purpose-built to efficiently reduce the size of large bulk waste from injection or blow moulding, as well as extrusion processes. Its primary function is to chop down oversized materials before they undergo granulation and preprocessing, significantly reducing energy consumption.

- Plastic recycling operations

- Industrial material shredding

- Wood off-cuts processing

- Textile waste reduction

- Injection molding scrap

- Blow molding waste

- Extrusion process leftovers

- Bulk waste size reduction

This equipment processes all categories of plastic materials, converting them into uniform shredded pieces, thereby reducing waste volume and conserving natural resources. Particularly effective for large plastic items and diverse industrial plastic scraps, it represents an essential tool for modern recycling operations.

Implementation of our shredding technology enables businesses to enhance recycling efficiency, minimize environmental impact, and develop cost-effective waste management solutions.

Advanced Technology

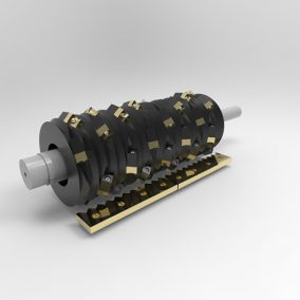

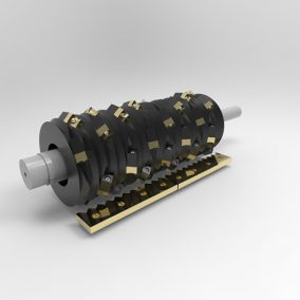

Shredder Rotor

The heavy rotor is equipped with a high-performance cutter designed to minimize energy consumption while efficiently processing various scrap materials with exceptional durability.

Control System

The PLC-based control panel incorporates comprehensive safety features and user-friendly operation, ensuring operational safety and equipment longevity with convenient monitoring and control.

Technical Specifications

| MODEL | PPM-400S | PPM-600S | PPM-800S | PPM-1000S | PPM-1200S | PPM-1500S | PPM-2000S |

|---|---|---|---|---|---|---|---|

| Main Motor (HP) | 10 | 20/30/40 | 20/30/40 | 20/30/40 | 20/30/40 | 20/30/40 | 20/30/40 |

| Knives Size (mm) | 14/24 | 25/40/75 | 25/40/75 | 25/40/75 | 25/40/75 | 25/40/75 | 25/40/75 |

| Rotor Speed (rpm) | 60-100 | 60-100 | 60-100 | 60-100 | 60-100 | 60-100 | 60-100 |

| Hydraulic Pusher | Yes | Yes | Yes | Yes | Yes | Yes | Yes |

| Rotor Diameter (mm) | 250 | 300 | 300 | 300 | 300 | 450 | 450 |

| Cutter House (mm) | 400/400 | 600 x 750 | 800 x 750 | 1000 x 750 | 1200 x 750 | 1500 x 750 | 2000 x 850 |

| Production (Kg/hr) | 50-75 | 200-250 | 300-450 | 400-600 | 500-900 | 800-1500 | 2000-4500 |

Payment Options

Contact Information

Address

Plot No. 127, GIDC, Umbergaon-396171, Gujarat, India

Phone

+91 7046463391

info@panchal-plastic.com

sales@panchal-plastic.com