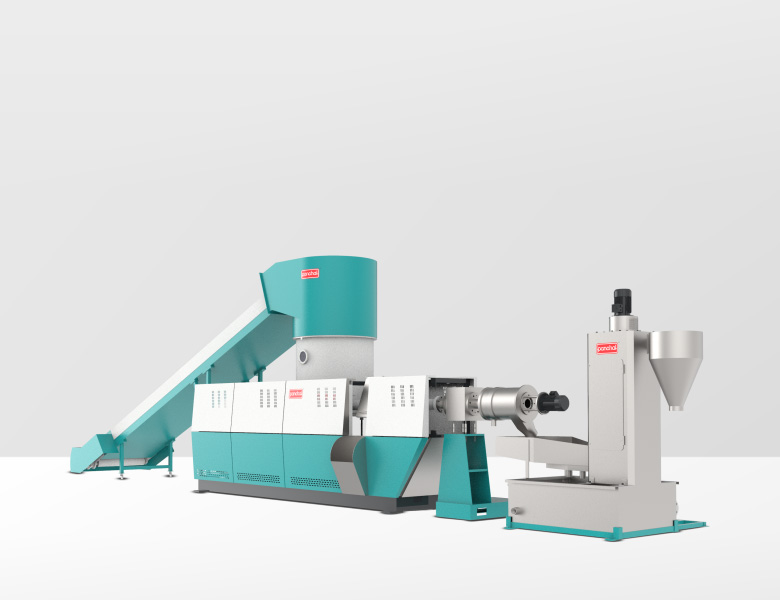

Cutter Compactor Plastic Recycling Machine

The Cutter Compactor Plastic Recycling Machine efficiently processes various types of plastic waste into high-quality reusable materials. This advanced 3-in-1 system combines cutting, compacting, and extruding technologies for optimal recycling performance and sustainability.

Cutter Compactor Plastic Recycling Machine

The All-in-One Recycling Machine specializes in the gentle conversion of trim, rolls, loose LDPE, LLDPE, HDPE, PP film, sheet, bags, and raffia waste into high-quality pellets, handling materials like plain unprinted film, film roll scrap, multilayer films (e.g., PE/PET/PP/PA), slightly printed films, and highly printed films.

Its advanced technical features include double and triple degassing with an agglomerator/cutter compactor, superior screw design, and extruder degassing, ensuring thorough degassing and improved melt characteristics through higher homogenization efficiency.

Economically, the machine excels by producing high-quality granules from challenging materials and reducing energy consumption by up to 30% with its Energy-SAVE system, alongside a compact design that further lowers production costs.

This comprehensive recycling approach ensures optimal performance and supports environmental conservation. Panchal's commitment to excellence is reflected in its advanced degassing processes, which improve the purity and overall quality of recycled materials.

Key Features of Our Cutter Compactor Recycling Machine

- Combination of Agglomerator and Extruder in one system

- Wide Range of Screw Sizes for different materials

- High Production Capacity for industrial applications

- Vented Extruder for efficient degassing

- Adjustable Granule Size for customized output

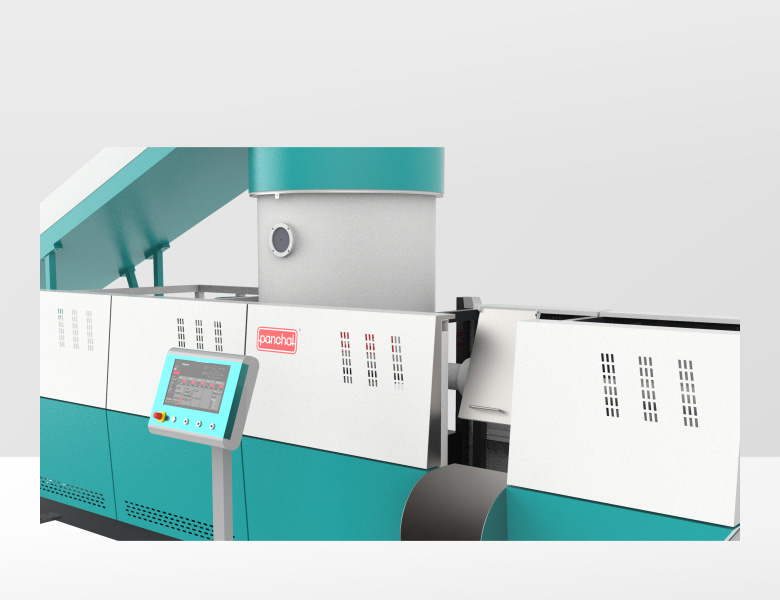

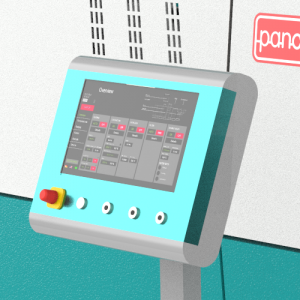

- Melt Pressure Transducer for precise control

- Energy-SAVE system reducing consumption by up to 30%

- Compact design minimizing footprint

Applications

The All-in-One Recycling Machine is designed for recycling different varieties of plant and production wastes being utilised in industrial processes such as:

- Films and sheets

- Rolls and monofilaments

- Raffia and textiles

- Powders and foam materials

- PE-LD, PE-LLDPE, PE-HDPE materials

- Blown and multilayer films

- Heavy printed or laminated films

- Metallized and cast films

This versatile machine processes materials including PP, PE, PE-LD, PE-HD, PS, PET, PLA, and BOPP, transforming them into high-quality reusable granules for various manufacturing applications.

Implementation of our cutter compactor technology enables businesses to enhance recycling efficiency, minimize environmental impact, and develop cost-effective waste management solutions.

Advanced Technology

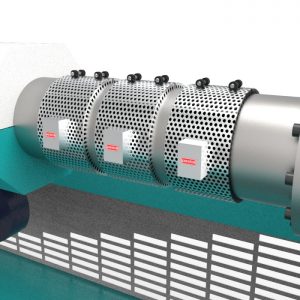

Ceramic Heating

Advanced ceramic heaters provide faster and more consistent heating with longer lifespan compared to traditional heating elements, ensuring efficient melting of plastic materials.

Extruder Screw

Advanced screw design ensures optimal homogenization of polymer, with specialized flight geometry that maximizes mixing efficiency and melt quality throughout the process.

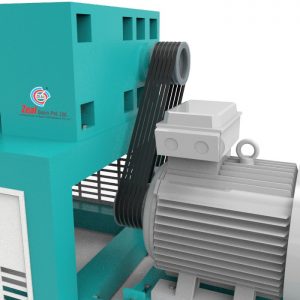

Gearbox System

Robust gearbox designed for high-speed performance and durability, capable of handling the torque requirements of continuous recycling operations with minimal maintenance.

Technical Specifications

| MODEL | PPM-65-IN | PPM-75-IN | PPM-85-IN | PPM-105-IN | PPM-125-IN | PPM-145-IN | PPM-165-IN | PPM-185-IN |

|---|---|---|---|---|---|---|---|---|

| Output (KG/HR) | 100-180 | 150-200 | 200-300 | 350-500 | 650-800 | 800-1000 | 900-1200 | 1000-1500 |

| Cutter (KW) | 22/30 | 30/45 | 45/55 | 75/90 | 90/100 | 132/160 | 132/160 | 200/250 |

| Extruder (kW) | 30/37 | 37/55 | 55/75 | 110/132 | 132/160 | 160/200 | 200/250 | 250/315 |

| NV Length | 26 | 26 | 26 | 26 | 26 | 26 | 26 | 26 |

| SV Diameter | 35 | 35 | 35 | 35 | 35 | 35 | 35 | 35 |

| DV/DHV | 42 | 42 | 42 | 42 | 42 | 42 | 42 | 42 |

Payment Options

Contact Information

Address

Plot No. 127, GIDC, Umbergaon-396171, Gujarat, India

Phone

+91 7046463391

info@panchal-plastic.com

sales@panchal-plastic.com